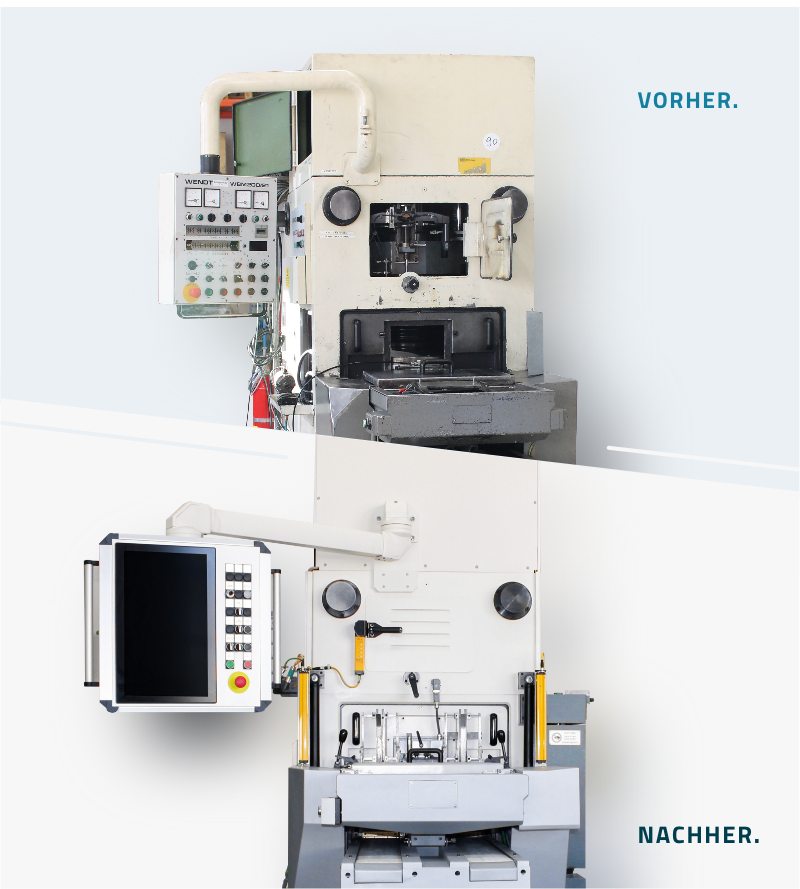

SHOULD I RETROFIT?

- Technical further development/ modernisation of the already discontinued series.

- Better future spare parts supply through the use of current components.

- Increase in precision and quality. Productivity, availability and output.

- Fulfilment of legal requirements (e.g. occupational safety incl. CE marking).

- Integration into Industry 4.0.

- Connection of automation and robotics possible.

- Much lower in cost (up to 60%).

- Installed machine bed remains in place.

- Particularly sustainable.

- Boost to productivity and output.

- Improved reliability.

- Less training work involved.

Possible retrofit measures

The following assemblies are exchanged and work is carried out:

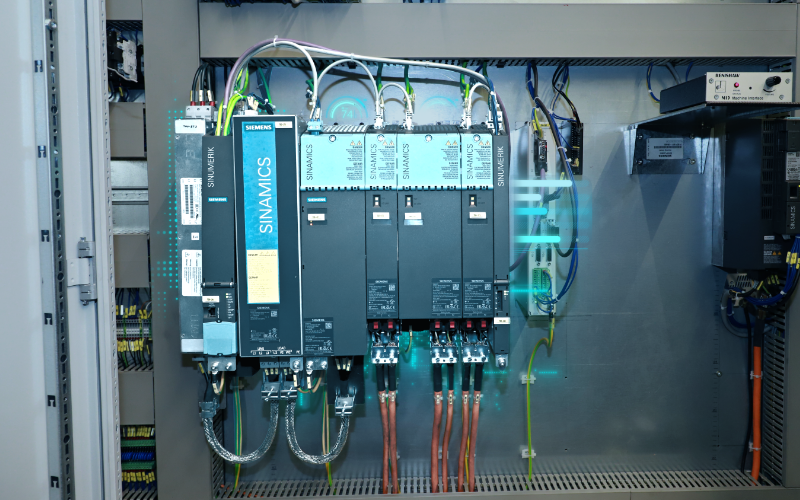

- Control: Siemens Sinumerik 840Dsl; Sinumerik One

- Peripherals: Siemens Simatic S7-1500; ET200 MP; ET200SP (scalable, modular, and highly flexible).

- Circuit diagram: Creation on CAD EPLAN P8

- Rewiring

- Control cabinet from Rittal Replacement of sensors and actuators

- New installation

The following measures are implemented for a modern operating concept:

- Large touch screen

- Open IPC concept with optimal diagnostic possibilities

- Siemens industrial PC

- Implementation in Siemens TIA Portal

- Control panel incl. monitoring system

- Advanced HMI software (panel or PC based).

- Optional: Mobile Panels

To be renewed:

- Bearing of grinding and dressing spindles/ dressing unit.

- Gear wheels

- Hydraulics (pump; piping/hoses)

- Linear guides

- Trapezoidal thread spindle

- Directional valves

- Pressure valves

- Cylinders

- Lubrication: power unit; pump; distributor; central lubrication.

- Coaxial valves/ Coaxial valves for coolant

- Coolant piping

- Exhaust system

- Bicolor painting of the machine by means of shock-proof corrosion coating (according to individual customer’s request).

We offer the following individual solutions according to the latest guidelines:

- Additional light curtains/ light barriers

- Electrical (maintenance) door interlocks/ locking devices

- Level switches against overflow

- Protective fences and grids

- Work area lighting

- Individual adaptations to loading and unloading systems, e.g. by integrating robot systems from the following

- manufacturers: Kuka, Fanuc, ABB, Omron.

- Complete automation concept

- Control systems

- Storage/ magazine loader

- Transport storage system

Together with you, we conduct a needs analysis of the scope of the retrofit in advance, as well as the individual planning.

After the retrofit we offer you

- Machine installation on site

- Running-in of the machine with workpiece

- Recommissioning

And even after that, you can rely on us. Our service offer includes:

- In-house electronic and mechanical service

- Life cycle management

- Fast response time

- Personal contact persons

- Optional 24/7 online shop

- 25 months warranty on retrofit scope

- 40,000 immediately available spare parts and assemblies directly from stock

WENDT

6 twin spindle plane grinding machines

NAXOS-UNION

Round grinding machine

TBT

Deep drilling machine

BÖHRINGER

Milling machines and lathes

MÄGERLE

10 surface grinding machines

SIELEMANN

Round grinding machine

FELSOMAT

Loader systems

RAVENSBURGER

Milling machines and lathes

ABA

3 surface grinding machines

KEHREN

Round grinding machine

HELLER

Machining centre

GILDEMEISTER

Milling machines and lathes

ELB

Surface grinding machine

JUNG

Surface grinding machines, internal cylindrical grinding machines

EX-CELL-O

Machining centre

DÖRRIES

Milling machines and lathes

WALDRICH COBURG

6 guide-track grinding machines

TIBO

Deep drilling machine

SCHARMANN

Machining centre & milling machines and lathes

SCHÜTTE

Milling machines and lathes